Get In Touch Today (07) 4785 6227

Providing Professional Welding in Collinsville

Metal Welding

Our skilled group of craftsmen possess expertise in various facets of metal fabrication and welding, ensuring top-notch quality in both products and services for each project. Our proficiency extends to working with a wide array of materials, including:

- Steel

- Stainless steel

- Aluminum

- Carbon steel

- Galvanised steel

- Zincanneal

- Checker plate

- Treadplate

- Perforated metal

- Mesh

- Expanded metal

- Tubes

- RHS (Rectangular Hollow Sections)

- Angle bars

- Flat bars

- Fittings

ADR Engineering can repair, maintain and modify mobile machinery and fixed plant, either at our workshop in Collinsville or on-site at your premises in Bowen, Moranbah, the Bowen Basin, Emerald or the Whitsundays. For reliable and efficient service, call us at (07) 4785 6227 today.

StructurAl Welding

The team at ADR Engineering are experts in structural welding—both from their workshop in Collinsville or on-site at your premises. We not only create metal frameworks for vehicles, buildings, bridges and other complex structures—we also cut and repair beams, columns and girders.

Our structural welders apply their precision in stick, stock and flux core welding for the mining and agricultural industries.

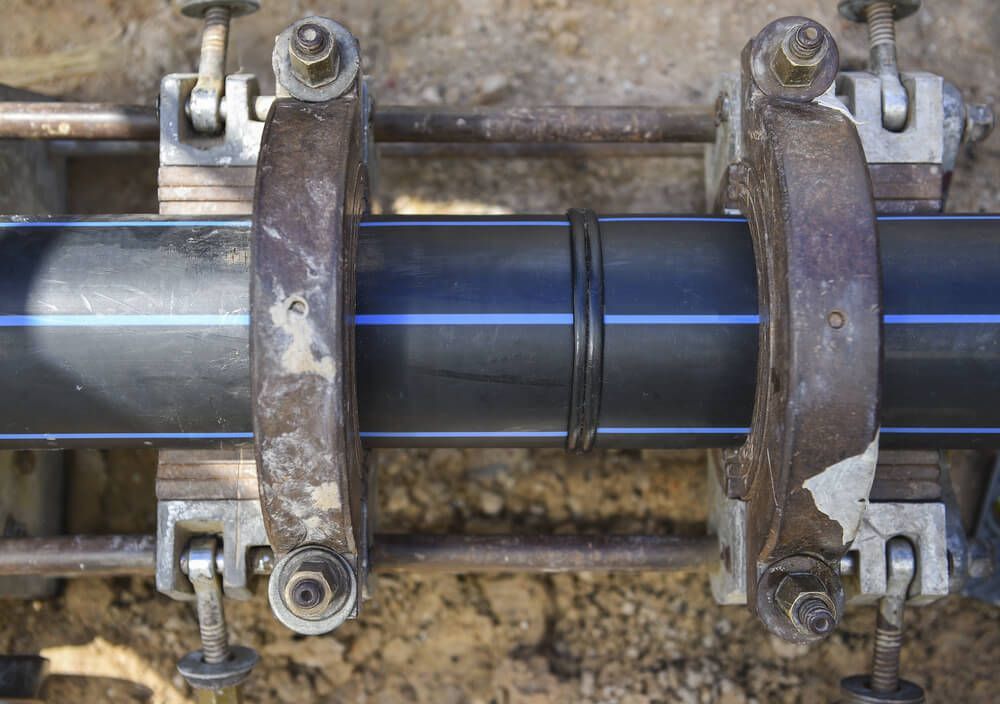

Poly Welding

Like steel, Polyethylene (Poly) can be welded with the right tools and experience. ADR Engineering specialises in poly welding (up to 350mm diameter) in Collinsville, Bowen, Moranbah, Emerald, the Bowen Basin and the Whitsundays.

Poly welding unites softened surfaces of semi-finished plastics, generally through the use of heat. The three-step process involves surface preparation, applying heat and pressure, then cooling.

Numerous methods have been developed for joining semi-finished poly materials—both internally and externally. For internal poly jobs, we use extrusion, hot plate and butt heat fusion welding. For internal poly jobs, we utilise electrofusion and electric resistance welding.

We also have an ET GVN and a wide range of stock on hand for poly crack repairs.

Joining Poly Pipes

The personnel at ADR Engineering are trained in all aspects of butt fusion and electrofusion welding of thermoplastics. No job is too complex for our team.

Butt fusion is commonly used for joining large lengths of high-density Polyethylene (PHDPE) pipe. A butt welding machine holds, scrapes and heats the two pipe ends before hydraulically pressing them together. The machine holds them until the join cools, creating the weld.

Electrofusion welding also joins HDPE—and other plastic—pipes using special fittings with built-in electric heating elements. Cleaned joints are inserted into the fitting and voltage applied.

The built-in coils melt the inside of the fitting and the outside of the pipe wall, producing a strong weld after the joint has cooled.

Explore

Services

Gas & Steel Supply

Trading Hours

Mon - Thurs:

08:00 am - 5:00 pm

Friday:

08:00 am - 2:00 pm

Sat / Sun / Public Holidays:

Closed

ABN: 52 098 290 718

Refrigerant Trading Licence: AU40618

Structural Welding Certification: AS1554.1